- #Camworks post left hand how to#

- #Camworks post left hand manual#

- #Camworks post left hand full#

- #Camworks post left hand software#

- #Camworks post left hand trial#

if you machine many pockets with islands then you need to optimize the database to give you the results you require. AFR works good once you configure it in relative to the type of jobs you do, e.g. My rep ain't the best either, but with my experience I was able to overcome these issues. PS: I also heard good things about SolidCAM from a reliable source, afraid I haven't tried it.īig_mak you got a dud rep it seems.

I'd take a gamble here and say that 80% would choose CAMWorks. So once you can see how much or how little ultimate control you have in the end process, it should be easy to decide on the package. One other thing is chamfer cutting, there is not many packages that will allow you to cut a chamfer with a few clicks (CAMWorks does).

#Camworks post left hand how to#

And then dive in deep and learn the behind the scenes stuff of the CAM package, the settings the knowledge libraries, how to modify or add your own data. If they want your business they will do it.

#Camworks post left hand software#

In the end the most important thing is to bug the hell out of your software reps for demos, get them to extend your demo license to a month. For multi axis no need for AFR, you machining strategy most often varies across the one job. You do need to tweak it every now and then, but hey no other package comes even close. Nothing.Īs far as AFR, you need to configure the software to your requirements and it will do 90% of your 2.5 axis tool paths automatically. Dig in deep thats where the answers are, not in the top icon bar, well with CAMWorks there is plenty do find, but the others. How can you get is wrong? LAZY.Įveryone seems to spend endless hours researching tooling and machinery, but when it comes to software, they write it off just because they cant figure something out in a few hours. Not only that the simulation is spot on, the best in any CAM package I've seen. The provision is there for you to automate all global and local retracts, rapids, skims, lead ins, lead outs, speeds and feeds for each machining process even each tool type and or size. Someone mentioned the rapids gouging their die work, YOUR FAULT. The CAMWorks tutorials are great, they tech you the basics on which you need to add your own knowledge and understanding and be prepaired to do some experimenting. I'm about to offend a heap of people, as far as I'm concerned it seems that people are just too damn lazy. A week later I purchased two 5 axis licenses, will not be updating my ProE license. Perfect tool paths, straight forward stuff.

#Camworks post left hand trial#

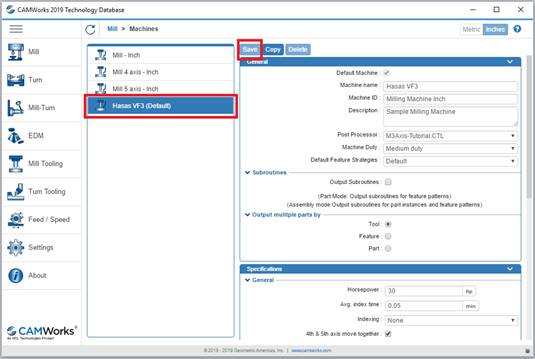

And was cutting 4 and 5 axis simultaneous trial jobs in three days. I optimized the post in no time, very common sense stuff here. I was given a demo of CAMWorks, I have plenty of experience with solid works.

Maybe a good brain washing or lobotomy will be easier. Some one mentioned you need to unlearn what you already know about CAM to use Gibbs, I agree. GibbsCAM lets not even go there, the most backward package on the market. ProE has gone the same way, overly complex for no extra benefit. The latest Mastercam is junk, you need work arounds for everything you could imagine in multi axis. I have been using ProE and Mastercam for many years. If you have a copy of an MSC catalog around the office, have a look at the tapping tool section - there is a discussion of tap terminology there.īTW, aside from a spelling problem (protusion?) the protrusion values in the table are incorrect - tap sticks out beyond just the flute length in most cases.I don't understand why people are complaining about CAMWorks.

#Camworks post left hand full#

Software needs this info to know how far to drive tap into material to achieve full thread to the desired depth. I suspect they are all 0s because it varies depending on the type of tap involved (plug, bottoming, etc.). length (Ineffective, inefficient?) are the partial threads at the beginning of the tap. The shoulder length (L4) + flute length (L2) + Ineff.

#Camworks post left hand manual#

I suspect it has something to do with the intended audience, but this is not the first, or last, technical manual you will encounter that left out significant data.however, to the task at hand Īs Rainman said earlier, shoulder length relates to change in diameter of the tool in this case it is the length of the tap behind the flutes (shank smaller than cutting diameter) to the end of the tool. You're right - why put all those parenthetical dimensions under the headings and not show them in the cartoon. Well, now you know how some folks my age (old) felt about programming VCRs.

0 kommentar(er)

0 kommentar(er)